In the realm of modern manufacturing, precision and efficiency are paramount. As industries demand increasingly complex and high-quality components, the technology behind machining has had to evolve to meet these challenges. Enter the 5-axis machining center—a revolutionary piece of equipment that has transformed the way we approach manufacturing. This article delves into the intricacies of 5-axis machining, its advantages, applications, and the future it promises.

What is a 5-Axis Machining Center?

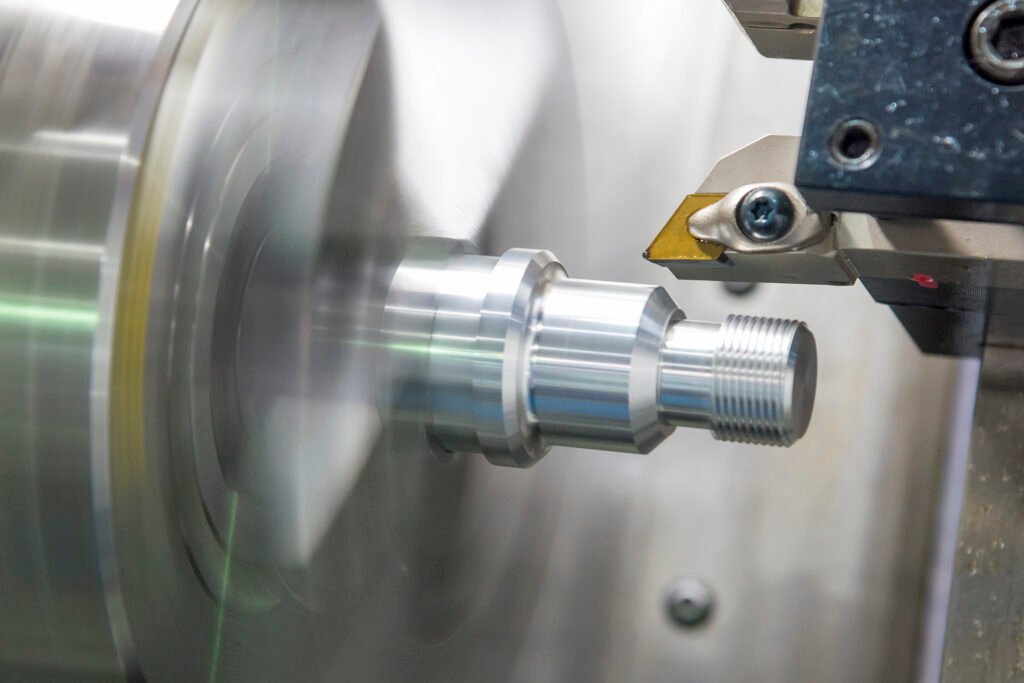

A 5-axis machining center is a type of CNC (Computer Numerical Control) machine that operates on five different axes simultaneously. Unlike traditional 3-axis machines, which move along the X, Y, and Z axes, a 5-axis machine adds two rotational axes, typically referred to as the A and B axes. This additional movement allows the cutting tool to approach the workpiece from virtually any direction, enabling the creation of highly complex geometries with unparalleled precision.

The Advantages of 5-Axis Machining

- Enhanced Precision and Complexity: The ability to move along five axes allows for the machining of intricate shapes and contours that would be impossible or extremely time-consuming with a 3-axis machine. This is particularly beneficial in industries such as aerospace, automotive, and medical devices, where complex components are the norm.

- Reduced Setup Time: With a 5-axis machine, multiple sides of a workpiece can be machined in a single setup. This eliminates the need for repositioning the workpiece, reducing setup time and minimizing the risk of errors associated with manual adjustments.

- Improved Surface Finish: The continuous movement of the cutting tool along multiple axes results in a smoother surface finish. This is especially important for components that require high aesthetic standards or must meet stringent tolerances.

- Increased Tool Life: By optimizing the cutting path and reducing the need for multiple setups, 5-axis machining can extend the life of cutting tools. This not only reduces costs but also enhances the overall efficiency of the manufacturing process.

- Versatility: 5-axis machining centers are incredibly versatile, capable of handling a wide range of materials, from metals to composites. This makes them suitable for a variety of industries and applications.

Applications of 5-Axis Machining

The versatility and precision of 5-axis machining centers make them indispensable in several industries:

- Aerospace: The aerospace industry demands components with complex geometries and tight tolerances. 5-axis machining is used to produce everything from turbine blades to structural components.

- Automotive: In the automotive sector, 5-axis machining is employed to create engine components, transmission parts, and custom prototypes.

- Medical Devices: The medical industry requires highly precise and intricate components, such as implants and surgical instruments. 5-axis machining ensures that these parts meet the necessary standards.

- Mold and Die Making: The ability to machine complex shapes with high precision makes 5-axis machining ideal for creating molds and dies used in various manufacturing processes.

The Future of 5-Axis Machining

As technology continues to advance, the capabilities of 5-axis machining centers are expected to grow even further. Innovations in software, such as advanced CAM (Computer-Aided Manufacturing) systems, are making it easier to program and optimize 5-axis machining processes. Additionally, the integration of AI and machine learning could lead to smarter, more adaptive machining centers that can self-optimize in real-time.

Moreover, the rise of additive manufacturing (3D printing) is not seen as a replacement for 5-axis machining but rather as a complementary technology. Hybrid machines that combine additive and subtractive manufacturing processes are already emerging, offering even greater flexibility and efficiency.

The 5-axis machining center represents a significant leap forward in manufacturing technology. Its ability to produce complex, high-precision components with reduced setup times and improved surface finishes makes it an invaluable tool in modern industry. As technology continues to evolve, the potential applications and capabilities of 5-axis machining are bound to expand, further solidifying its role as a cornerstone of advanced manufacturing.

In a world where precision and efficiency are more critical than ever, the 5-axis machining center stands as a testament to human ingenuity and the relentless pursuit of perfection in manufacturing.