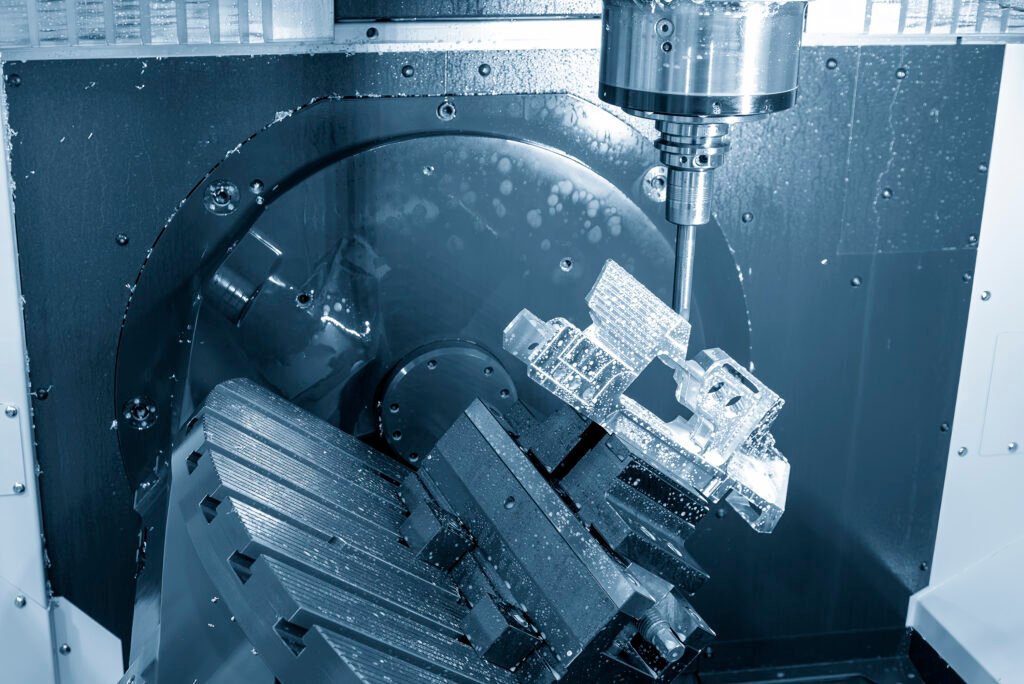

In recent years, 5-axis CNC machining centers have been widely used in various fields. When encountering complex and irregular-shaped parts that require higher efficiency and quality, the use of 5-axis machining technology is undoubtedly an important solution to these challenges. More and more manufacturers are looking for 5-axis equipment to meet the demands of high efficiency and high-quality machining.

Advantages of 5-axis machining:

- No special fixtures are required during machining, reducing fixture costs, avoiding multiple setups, and improving mold machining accuracy.

- Reducing the number of fixtures used.

- Many special tools can be eliminated during machining, thus reducing tooling costs.

- The effective cutting edge length of the tool can be increased during machining, reducing cutting forces, improving tool life, and reducing costs.

When machining deep and narrow areas in mold cavities, 5-axis machining is undoubtedly a good choice.

The advantage of 5-axis machining is that it allows the tool feed direction to maintain a continuous and suitable angle with the workpiece surface, resulting in better surface quality. It also allows better access to chamfers and improves tool life. The utilization of tools is more economical, cycle times are reduced, and one-time setups are possible, saving time and reducing the error rate in machine tool processing.