Since stainless steel components are difficult to machine, there are various challenges that need to be overcome during the machining process. What are some of the difficulties that need to be addressed when machining stainless steel components?

Difficulty 1: Stainless steel parts have high hardness, which accelerates the wear of machining tools.

Solution: Use machining tools with high thermal conductivity.

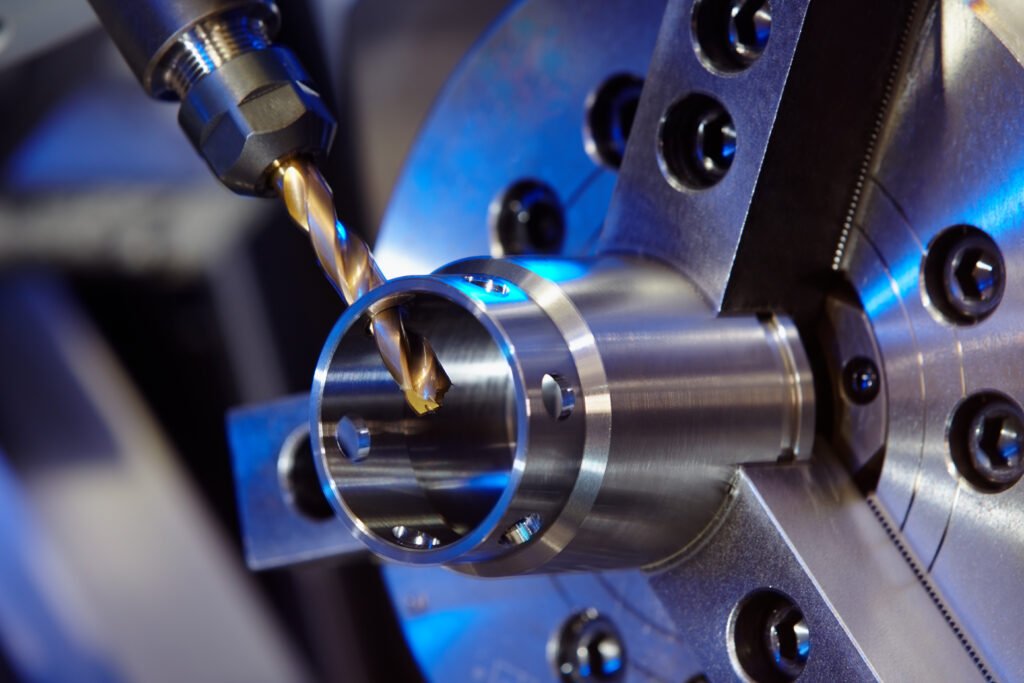

Difficulty 2: Difficulty in chip removal during machining of stainless steel parts.

Solution: Use sharp cutting edges and wider chip grooves to reduce cutting pressure and better control chip removal.

Difficulty 3: Accumulation of debris can result in poor surface quality during machining.

Solution: Select suitable cutting fluid to reduce the accumulation of debris.

Difficulty 4: The chemical interaction between machining tools and stainless steel parts can lead to tool chipping, abnormal fracture, and work hardening.

Solution: Choose machining tools with high toughness, high cutting edge strength, and high adhesion of coating films.