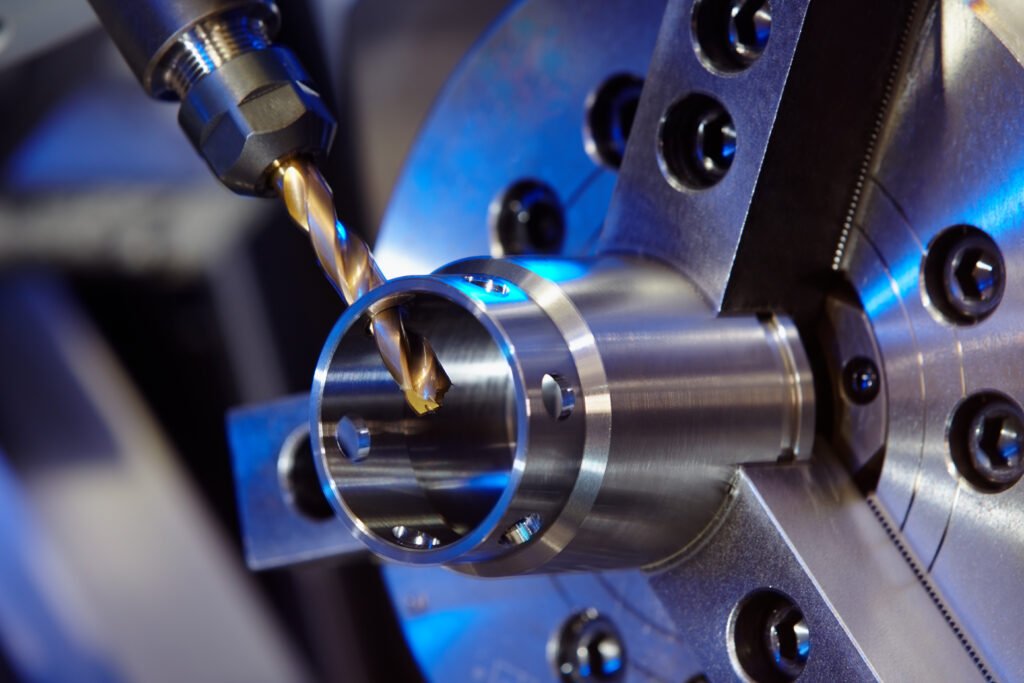

During the machining process of mechanical parts, various factors such as plastic deformation of the metal surface during cutting, vibration of the machining machine tool, and the tool marks left on the surface by the tool will affect the surfaces of the machined parts. Regardless of how smooth the machining is, when observed under a microscope, the unevenness of peaks and valleys can still be seen.

The micro-geometric shape characteristics composed of peaks and valleys with small spacing on the machined surface are called surface roughness. Generally speaking, different machining methods result in different surface roughness.

The roughness of a surface has a significant impact on mechanical products.

- Surface roughness affects the wear resistance of parts. The rougher the surface, the smaller the effective contact area between mating surfaces, resulting in higher pressure and faster wears.

- Surface roughness affects the stability of fit properties. For clearance fit, a rough surface is more prone to wear, leading to gradual increase in clearance during operation. For interference fit, the micro-level peaks are flattened during assembly, reducing the actual effective interference and weakening the joint strength.

- Surface roughness affects the fatigue strength of parts. Rough surfaces have larger troughs, which are sensitive to stress concentration similar to sharp notches and cracks, thereby affecting the fatigue strength of the parts.

- The corrosion resistance of parts is affected by surface roughness. A rough surface makes it easy for corrosive gases or liquids to penetrate into the inner layers of the metal through the microscopic grooves on the surface, causing surface corrosion.

- The surface roughness affects the sealing of parts. Rough surfaces cannot fit tightly together, allowing gases or liquids to leak through the gaps between the contact surfaces.

- The surface roughness affects the contact stiffness of the parts. Contact stiffness refers to the ability of the part’s mating surfaces to resist deformation under external forces. The stiffness of the machine depends largely on the contact stiffness between the various parts.

- It affects the measurement accuracy of the parts. The surface roughness of precision machined parts and the measurement surface of the measuring tool directly affect the accuracy of the measurement, especially in precision measurements.

Furthermore, surface roughness can have varying degrees of impact on the part’s coating, thermal conductivity and contact resistance, reflectivity and radiation performance, resistance to liquid and gas flow, and conduction of surface current for conductors.